Case of the Missing Pineapple Solved

by F.C. Tabor

After graduating from Navy Metalsmithing School, we fledgling

weldors (years ago, "Welding Engineer magazine tried to differentiate between the machine "welder" and the operator "weldor" by spelling the two differently had the notion that we were ready to tackle anything from a rowboat to a battlewagon when it came to welding.

When we got out on a high seas with the fleet, we soon discovered that a lot of items we encountered had not been mentioned in trade school books.

At Pearl Harbor I was assigned to a repair ship that went to Eniwetok in the Marshall Islands.

We fixed anything except major damage.

Above water-line repairs were done alongside our ship, and a floating dry dock was available for bottom work.

On one of our "alongside" jobs, the other welder and I decided that it would be easier to let "Old Man Pacific" be our ground lead.

Why spend the effort dragging a ground cable over to the repair job, when water is such a good conductor?

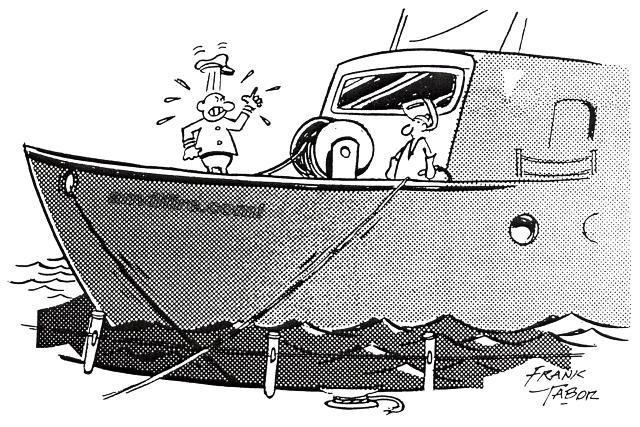

So, we just pulled over our stinger and proceeded to do the necessary welding, that is, until the skipper spotted the missing ground, whereupon the proverbial material hit the fan head-on and splattered wildly in all directions.

When the captain's long, drawn out scream had finally died away in the tropical breeze, he explained that, even through sea water made a dandy ground, the returning electrical energy had an electrolysis effect and would slowly eat holes in our hull.

As the old adage goes, "Live and learn . . "

Some of the things we fixed would not take a prize at a metal craft show, but they filled the need.

On one project, a mine sweeper skipper pulled alongside and asked us to install extra shelves in a food locker that was one deck down at the bow.

Access to the locker was by a "porthole" on the main deck.

It was a round entry way a little smaller than your regular street manhole.

After we had the pieces cut for the shelves, we discovered they wouldn't go through ~ Manhole in the deck.

The only thing we could do was "roll" them enough to get them below, then hammer the shelves flat again for installation.

That was a real fun job in close quarters So much fun, in fact, that several cans of pineapple disappeared from that pantry to quench our tropical thirst.

* Originally published in Northwest Metalworker

Case of the Missing Pineapple Solved

by F.C. TaborAfter graduating from Navy Metalsmithing School, we fledgling weldors (years ago, "Welding Engineer magazine tried to differentiate between the machine "welder" and the operator "weldor" by spelling the two differently had the notion that we were ready to tackle anything from a rowboat to a battlewagon when it came to welding. When we got out on a high seas with the fleet, we soon discovered that a lot of items we encountered had not been mentioned in trade school books.

At Pearl Harbor I was assigned to a repair ship that went to Eniwetok in the Marshall Islands. We fixed anything except major damage. Above water-line repairs were done alongside our ship, and a floating dry dock was available for bottom work.

On one of our "alongside" jobs, the other welder and I decided that it would be easier to let "Old Man Pacific" be our ground lead. Why spend the effort dragging a ground cable over to the repair job, when water is such a good conductor? So, we just pulled over our stinger and proceeded to do the necessary welding, that is, until the skipper spotted the missing ground, whereupon the proverbial material hit the fan head-on and splattered wildly in all directions. When the captain's long, drawn out scream had finally died away in the tropical breeze, he explained that, even through sea water made a dandy ground, the returning electrical energy had an electrolysis effect and would slowly eat holes in our hull. As the old adage goes, "Live and learn . . "

Some of the things we fixed would not take a prize at a metal craft show, but they filled the need. On one project, a mine sweeper skipper pulled alongside and asked us to install extra shelves in a food locker that was one deck down at the bow. Access to the locker was by a "porthole" on the main deck. It was a round entry way a little smaller than your regular street manhole. After we had the pieces cut for the shelves, we discovered they wouldn't go through ~ Manhole in the deck. The only thing we could do was "roll" them enough to get them below, then hammer the shelves flat again for installation. That was a real fun job in close quarters So much fun, in fact, that several cans of pineapple disappeared from that pantry to quench our tropical thirst.

* Originally published in Northwest Metalworker